At Sea Bags, Sustainability is at the Core of What We Do.

Have you ever wondered what it takes to keep more than 700 tons of sails out of the landfill? Because we’ve been repurposing sails since 1999, it’s second nature to us, but requires a lot of planning and hard work. From sourcing sails and washing them, to tracing panels and cutting the sail down, each sail is handled by a variety of craftspeople before it’s finally stitched into a coveted Sea Bag. Come along as we dive deeper into our process of saving sails from landfills.

07/29/21

What is the Sea Bags process?

We spoke with our Production Manager, Dillon Leary, and asked him to walk us through what happens from the time the sail gets to the warehouse to when it is stitched together to create a bag. He explains, “We cut sails literally all day long. It’s an ongoing process of receiving, sorting, prioritizing, cutting, washing, and then distributing to different areas of production for use.” Dillon says that one of the most interesting aspects about our raw materials is that each sail is different. “Once they are received, they are sorted based on size, quality, and weight. Each one can differ in thickness, type of stitch, and specific type of dacron.” Sails differ in weight and type of fabric based on their use, whether for cruising or racing, as well as the size and weight of the boat. Similar to how heavier weight sails are used for bigger boats, we delegate our thicker sail cloth to our larger totes, as they are expected to carry a larger load.

Utilizing as much as the sail as possible

When we say we try to utilize as much of our recycled sail cloth as possible, we mean it.

We start by stripping off hardware, ropes, and battens and save the sail trim, all to be re-used elsewhere. The weatherworn hardware, called hanks, can be found in our retail stores as add-ons to bags or sold as keychains. Quality rope is mostly set aside for special projects but is also re-used around the warehouse for pallet strap replacements, laundry lines in the parking lot, and fixture tie-downs in the van.

The sails are then cut by hand on our “cutting floor”. Hak, one or our sail cutters, traces and cuts handbags and totes. After this initial cut, the leftover sail pieces get sorted based on the same factors: size, quality, and weight. These sail remnants are sent to our die-cutter to be cut into smaller shapes, like buckets, wristlets, and wine bags. What remains after this cutting is what most would consider scrap, but at Sea Bags, it’s one of the most cherished pieces of the bag. Our branded hang tags that are affixed to all Sea Bags products are cut from the final cutting scraps so we leave no piece of sail unused. Many customers choose to leave these hang tags on their bag, and others repurpose them into bookmarks, Christmas ornaments or garden markers.

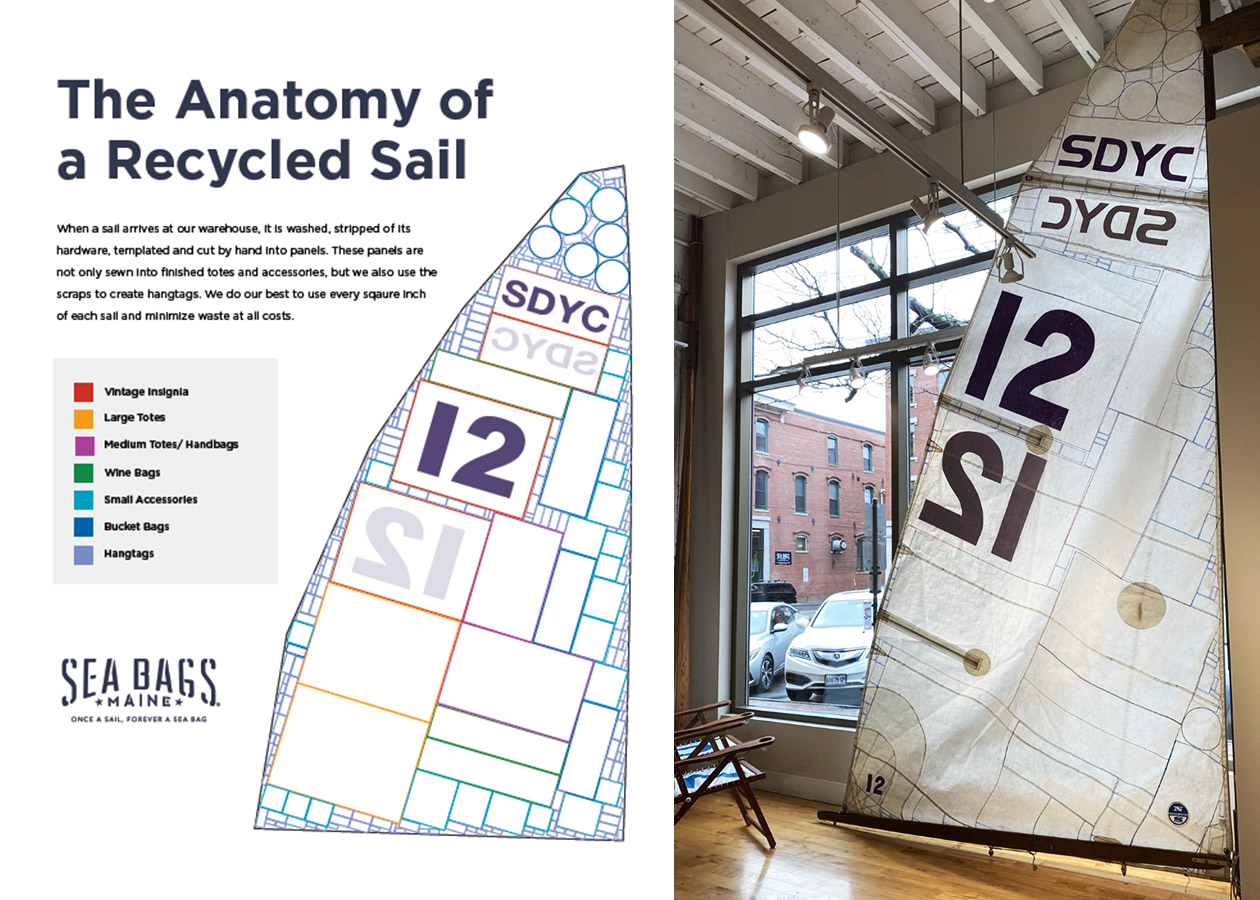

When we opened our new Flagship Store in Portland, Maine, we decided to show customers what a templated sail looks like and how we can use every bit of sail cloth. This towering display that we call “The Anatomy of a Recycled Sail” lives in the window of our store to illustrate just how much effort is involved in reclaiming sails and repurposing the sail cloth into a second, useful life as Sea Bags.

What are the challenges we face when utilizing recycled materials?

Supply and demand is the name of the game, but this can get tricky when filling certain orders using recycled sail cloth. Over the years, our team has identified the types of sail cloth that work best for different types of bags. For example, stiff, rigid sails are best for buckets while thinner sails are great for wristlets. Dillon describes a potential issue, “Because the material is 100% recycled, I have no control over what we receive. This means that a delivery of recycled sails could be entirely rigid sails, which are only good for buckets. But that week I may need to cut panels for wine bags and totes based on orders we need to fulfill, so those sails aren’t the best fit.” A scenario like this often means searching through backstock to find an appropriately sized sail made from the correct type of dacron to fulfill those specific orders. He goes on to say, “If we purchased our material, it would certainly be easier, but we wouldn’t be able to make the environmental impact we are able to, so it’s worth it.”

Why is it important to keep sails out of the landfill?

We’re proud to have kept 700 tons of sails out of the landfills. But why is this important? It’s long been known that garbage that ends up in landfills can contribute to water pollution, air pollution, and release greenhouse gases into the atmosphere. Sails that end up the landfill can take hundreds of years to decompose. By recycling the sail cloth into our products, this not only keeps them out of landfills, but cuts down on the energy needed to source, extract and fabricate new materials. All of this in turn helps to conserve the Earth’s limited natural resources.

If you have any sails that you would like to donate, follow this link to learn how to participate in our Sail Trade Program.

SHARE YOUR

#SEABAGSIGHTING

Signup for email,

and Save 10%!